by Mike Borgelt of Borgelt Instruments

Mike Borgelt is a physics graduate of the University of Western Australia, a qualified meteorologist, and has been flying gliders since 1966. He is a former Australian 15 Meter Class National Champion, holds a Private Pilot Licence for single engine land aircraft, and owns a BD-4. Since 1978, Mike and his wife, Carol have been designing and manufacturing sailplane instruments in Australia with thousands of instruments sold world wide under the Borgelt Instruments label.

Occasional other projects have seen Borgelt Instruments expertise used in keeping grape juice at the right temperature while fermenting, keeping little green apples happy in cool stores, helping the Australian Government print bank notes on plastic, helping farmers get the optimum irrigation water pumps and monitoring their seeding equipment, testing aircraft for the Royal Australian Air Force and Civil Aviation Authority, and a human factors project for the Australian Defence Science and Technology Organisation.

For those who may be interested, here’s a story of the sometimes fortuitous and serendipitous development path of a couple of new variometer systems and a description of their features.

Originally the design of these new variometers began in September 2010 at the start of the Queensland State gliding championships (later cancelled due to weather – it rained) when I saw an Oudie for the first time. I was impressed by this device and had the idea to interface a B500 main system unit (the part that mounts in a panel hole) with the Oudie, send B500 air data to the Oudie and have the Oudie send MacCready, bugs and ballast settings to the B500 and use its own internal GPS for position data. This would make a simple low cost system with excellent variometer plus color display moving map and glide computer. Naviter, the Oudie people, assure me they will make the Oudie capable of this eventually (at present Oudie can read only one serial datastream – either the external one or the one from the internal GPS). In the meantime our GPS module or a Flarm or Flight Recorder GPS data stream will make such a system work perfectly once Naviter have implemented the complete MacCready, bugs, ballast messaging from the Oudie.

Thinking about this on the drive home (we drove not flew – see comment about cancellation due to weather), I thought a digital averager display might be built in to the B400 and B500 variometer dials and this proved possible so combining these features looked to be a good idea.

Not long after this design was started, a young Dutch pilot, Adriaan Oudhuis approached Borgelt Instruments for a backup variometer to replace the mechanical vario in his ASW20. He was very keen on the Winter vario with the log scale but we were initially skeptical about the advantages of this. We did try making the audio more sensitive (more change per unit of lift) in the low range and found this to be very useful and incorporated it into the B400 audio right away.

After some airborne testing and a little interchange with Adriaan of some photoshopped dials for the scale, we agreed on a good looking logarithmic scale for the new variometer. It turned out to be easy to incorporate the log scale in the software driving the stepper motor pointer. The proposed design was run past some other pilots who unanimously liked the log scale. The only criticism was that because of the expanded low range the top range would be limited to 10 knots (5 m/s) instead of 12 knots as on the B400 and B500, and one pilot wanted to cope with the very strong thermals in Utah, said to be up to 12 to 14 knots. A little more thought resulted in a compressed scale at the top end going to 14 knots for those all too infrequent good thermals that exceed 8 knots. This gave us a scale that was sensitive in the low range (we all have to use less than 2 knots more than we like to admit and when we do, it is essential ) while coping with the strongest thermals without range switching. The audio and averager cope with up to 20 knots.

So the B700 came into being as a considerable enhancement of the B400 variometer, which has been used by contest pilots to replace the old mechanical varios and is also ideal for club or school two seaters or early solo gliders. Adriaan put the new vario to good use by winning a contest with it in his ASW20.

This all seemed like such a good idea that we decided to also replace the linear B500 scale with the B700 log scale and so the B800 was born. I now wonder why it took so long to realise the advantages of the log scale. I guess we got used to linear scales so Macready rings, which require a linear scale to work, could be fitted. Now that we don’t use MacCready rings we really don’t need linear scales on our variometers.

It was also decided to implement a whole thermal averager or integrator in the variometer, something that we considered on the well known B40 but didn’t implement on that instrument or its replacement, the B400. The digital averager display is switchable between running 20 second and total average but the calculations go on regardless of the switch position and the comparison is displayed using the amber and blue lights while climbing. These lights are also the speed command display on the B800 in cruise mode. This is an extension of our green light on the vario face concept which indicates that the current lift is above the 20 second average, which has been retained. Any time the current lift is above the average, the average is improving. Likewise when the current 20 second average is above the whole thermal value, the whole thermal value is improving. The whole thermal or integrated value is what determines your average speed cross country. There’s an audio warning when the 20 second average falls below 95% of the integrator value. The message here: It’s time to consider leaving or having a good reason to stay.

The audio also optionally has a subtle change in the on/off ratio of the beeps when the green light is on (green light off – 70% on 30% off, green light on 50% on and off) so you can tell by ear which side of the thermal is best and the ability to switch between “up only” audio, and “full range” (lift and sink audio) is retained while adding the ability to switch to our unique “full range but no sound in normal cruise sink range” audio, all from the front panel. The enhanced audio sensitivity in the zero to 3 knot climb range from late model B400s is present in both the B700 and B800.

This puts all the vario information required to optimise your climb on one dial and means one less information box on the Oudie screen when used with a B800. It means all the vario related information, including speed command, is in one place for efficient cruising. The B800 audio also has our unique “stereo” two speaker system for those who want to experiment with this. Enabling this does require the whole B800 system including GPS and GCD. The speed command audio is the same as that in the B500. The sounds for “fly faster” and “fly slower” are different from the climb and sink sounds and “fly faster” is only heard when you are flying slower than the speed for zero MacCready in the current airmass, while the audio will switch to climb sounds when the relative vario goes above the current MacCready setting.

There was then the problem of how to label the switches as there were enough functions that labeling was considered essential. Stick-on vinyl labels were briefly considered and rejected and so a bezel was devised to label the audio volume, averager/integrator and audio mode switches. Thanks to a suggestion by one of our suppliers, we have a low cost, robust and accurate way of making and printing these bezels and scales.

As we make our varios in both 57 mm and 80 mm standard instrument hole sizes (no ugly adapter plates required), this led to another problem. With meters per second and knots calibration and two sizes we potentially had four different meter scales to make and four bezels. This was a problem for a while until we concluded that the scale numbers could also go on the bezel and we realised that the bezels could be reversible – meters per second on one side and knots on the other – and so we wound up with only two bezels and two scales. This had the side benefit that all instruments were potentially metric or knots and easily field changeable making dealer stocking less of a problem too.

The B700 uses a potentiometer on the back and the B800 uses PC support software, but no disassembly of the instrument is required to swap calibration. While one meter per second is close to two knots, the relationship isn’t exact so we do the scaling correctly in the software setup.

We now had two new instruments with considerable hardware commonality with the B400/B500 (which remain in production), but with significantly enhanced functionality. Much of the well-proven B400 and B500 hardware is still present and much of the well-developed software could be re-used and refined.

The B700 is intended as a replacement for mechanical backup varios with its own low cost (four AA alkaline cells, good for 8 hours) standby power with considerably more usefulness in the event it is needed. You may be able to thermal without audio, but have you tried catching thermals on a high speed run without it?

For club or school training gliders, students can use audio and averagers to learn efficient thermalling techniques from the beginning. A back seat repeater is available and it even has all the controls. The repeater is the same as the B800 repeater.

The B800 behaves the same in climb mode but the case is a little longer than the B700 case because the B800 has an airspeed sensor so that air data can be fed to any glide computer software and advanced variometer processing like relative netto and speed command may be done.

Both cases are short and compact, easing installation, and are extremely robust with front and rear faces made from CNC machined aluminium plate 5 mm thick and covers folded from 1 mm thick sheet aluminum. The circuit board stack is supported at three points. We don’t want any issues due to mechanical stress on the electronics.

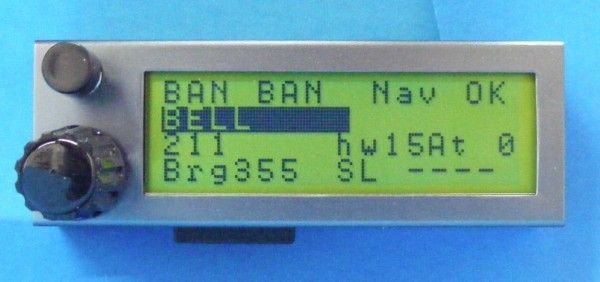

For the B800, there is the optional GPS module (4 solutions/sec) and our unique Glareshield Controller/Display (GCD) option which puts average, glide, wind and navigation information at your eye line in the top edge of the glareshield. No magic here, it is where the autopilot controls typically go in airliners and where the “up front controller” resides in the F/A-18 cockpit (I once had a half-hour ride in the Air Force’s F/A18 simulator). Typically it also puts the controls a little closer to you where they are easier to reach. No more difficult to install and well worthwhile in continued operational use. You install once, but use the instrument every time you fly.

We try to design our instruments to minimise mental processing and interpretation on the part of the pilot. Much of this is done in the software in the B700 and B800 and presented as a light pattern and sounds. With a really good audio vario the aim is to bypass the mental processing of thermalling altogether and have the audio cause the pilot to simply move the controls to maximise rate of climb. Our customers tell us that we are achieving this. One recent comment by a pilot flying with a B500 for the first time was, “I felt right at home and completely comfortable with the vario reponse and audio after only a few minutes”.

We took the opportunity to add our “Performance Index” concept to the GCD so in every glide after leaving the last thermal your loss of altitude is compared to the integrated loss of altitude for the speeds flown for the clean glider at that weight in still air. If you are only gliding at 85% or so in every glide there’s no point in planning a final glide at 100%. This lets you use the “bugs” setting to adjust the polar to something close to that being achieved. This is not the same as the way the “Performance Index” was incorrectly implemented in one earlier instrument, which was a running average and prone to being at one or the other limits much of the time, too often making it less than useful.

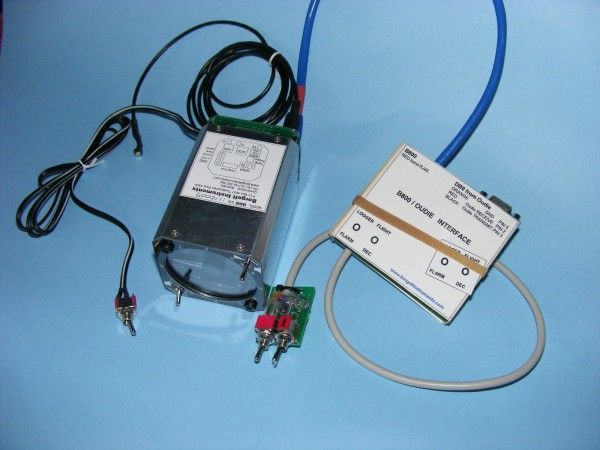

Many pilots like to have “Flarm radar” display on their moving map. To do this, it is necessary to integrate the Flarm into the B800/Oudie system.

As the Oudie comes with its own switch mode supply, we supply at lower cost a special Oudie-configured version of our PDA_PS (PDA Power Supply). Here, Flarm GPS, pressure altitude and target data is combined with B800 air data and the combined data stream is sent to the Oudie or other glide computer at 38.4 k baud.

Hence you can “mix and match” the B800 system to your requirements by adding or subtracting modules. Naturally, we suggest that for maximum utility out of the instrument that the GCD and our integrated GPS be fitted.

While the B800 was initiated with the Oudie in mind, other devices like the more recent cell phones with good, sunlight readable screens are excellent possibilities for connection to the B800 when running free software like XCSoar, which will shortly support the B800. Even Bluetooth connection should be possible with a serial to Bluetooth module plugged in to the Oudie Interface or PDA_PS outputs.

We haven’t forgotten about possible future developments. The data buss in both instruments is available externally (this feature is already planned for use in my Ventus twin jet self launch project – engine data will be displayed on the GCD when engines are running) and we’ve already flown some advanced inertial sensor packages and obtained interesting results. These new sensors are still rapidly improving, so rather than freezing the hardware at the present state of the art we will install the latest and best when the new concepts are ready for production.

Many thanks to those pilots who have provided inputs and opinions on these new instruments which have resulted in considerably improved features and functionality over the first concepts.

The B700 and B800 are now in production and being delivered. Customer response is very positive.

The main features of the new instruments are:

– unique lift trend displays and warnings, both audio and visual

– expanded scale in low range (+/- 2 knots or +/- 1 M/s)

– compressed in high range (+14 knots or +7M/s maximum indication), catering for all lift strengths without switching,

– better sensitivity (pointer movement per lift unit) in mid range than typical mechanical vario or LCD vario

– expanded audio sensitivity in low climb range

– digital display never obscured by pointer while climbing

– high contrast, high resolution stepper motor driven white pointer against black background – LCD pointers cannot compare!

– bright, clear colour LED indicators

– innovative and informative audio

– running average (AVERAGER) and total climb average (INTEGRATOR)

– only one instrument of each size (57 mm and 8 0mm), easily field changeable for knots or metric calibration.

– clear labelling of switch functions

– B700 has standard low cost emergency power pack

– a capacity flask free replacement for mechanical variometers and far and away more useful

– B800 includes airspeed sensor and is designed for interfacing to Oudie or other PNA/PDA type glide computers. Only one instrument hole required for B800 (57 mm or 80 mm)

– 0ptional soaring dynamics optimised 4 Hz GPS on B800 (same as B500GPS: 4 fixes/second)

– optional B800 “up front”, convenient, control/display unit with internal navigation, glide and wind computer display (GCD) (same as B500)

– future sensor technology under development for B800, interface already built in (wind vector estimation and horizontal gust elimination)

– common repeater to both instruments includes controls

– robust mechanical and electronic design

– glass front, not plastic

– field proven hardware and software, extended

– proven field reliability

– builds on six years of B400/B500 production and over 30 years of pressure transducer variometer production

– thousands of variometers in use worldwide

– same company, same owners

– designed and manufactured by a former championship soaring team and a software developer with soaring experience.

1 comment for “Designing the New B700 and B800 Variometers”