The Author

Georg Emanuel Koppenwallner has been a pilot since 1977 in Göttingen, FFG. He studied meteorology in Hannover and later on studied painting in Brunswick, Hochschule für bildende Künste Braunschweig. He has invented improved suction devices and blowers, e.g. the patented Coanda Cooker hood, US -6336451B1. Georg works as a painter on the Ikonografy of vortex flows and fluidic beings, “Fluidwesen,” and is a glider pilot who wants to fly in the Jet-Glider!

Preface

This article gives the worldwide community of glider pilots some more information about an idea that could give this sport a new impulse. In my practical work as a flying instructor, [it seems imperative that] a new way of teaching and flying must be created and the aircraft for this way must be invented. Winch launch and even towing launch need too many persons that are no longer available.

The glider of the future will be the self-launcher but not the retractable.

I look forward to comments, discussion or even support for other enthusiasts.

“Es gibt nichts Gutes, es sei denn, man tut es.” (“There is nothing good, unless, one does it.”)

Introduction

Soaring is not only the idea of flying without engine. Soaring is above all the branch of aviation which uses as little energy as possible energy and has, therefore, the lowest drag.

Modern sailplanes show a strong trend towards the self-launcher. In the mainstream of this trend are gliders with retractable engines, invented in the 1930s by John Valentine Carden in England and adapted by Wolf Hirth also in the 1930s in Germany.

This concept has a big advantage for the manufacturers. Without a major change of chassis or cockpits, an aircraft can be produced as a self-launcher as well as a motorglider. For the pilots, the advantage is the ability to launch themselves and to avoid outlandings. Today’s retractable engines, however, have serious disadvantages.

The flight security information V177 of the BFU[1] from May, 2012 describes the “risk of retractable engine“ (Risiko Klapptriebwerk) in outlanding situations. The retractable engine is also anything but a low energy propulsion method that would fit with the low drag of the glider equipped with it.

For both these reasons, security and energy consumption, new attempts have recently been developed for the propulsion of sailplanes: the turbine, the electric drive in the retractable engine, and the FES = Front Electrical Sustainer (see the article “Segelflugantriebe” in the April, 2011 issue of “Segelfliegen“).

Jet-Glider Propulsion

I would like to introduce the improved principle of an internal blower for propulsion with this article. “Internal blowers“ (inside within the fuselage or wing structure) are often driven by turbines. Nevertheless, to overcome the low drag and, therefore, for propulsion of a sailplane, normal electric motors or internal combustion engines are sufficient. However, the question is: Which blower should be used and how should it be inserted? Should it be an axial blower, the fan-like modification of the airscrew, or a radial blower?

Axial blowers with their big entry surfaces and the need of an undisturbed inflow have problems similar to those of the propeller. One does not know how to properly hide the entry surface when no propulsion is needed.

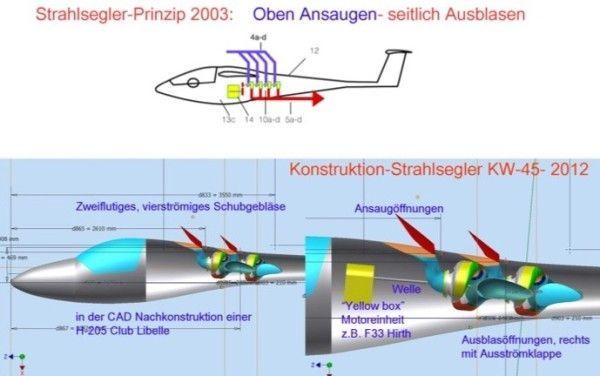

My proposal for a proper solution is to arrange several radial blowers one after the other so that the air flows are parallel. The air is sucked in from above and is blown out at the side. This is remniscent of the tandem principle where a driver sits in the lee of the other [Figure 2]. This works well with radial blowers, which can compensate the pressure losses in the in-duct and out-duct and the spiral housing. This pressure loss is the price of this arrangement. (Energy loss = Volumenstrom x pressure loss).

Evaluations show that the drag associated with this pressure loss is clearly lower than the drag of the propeller pylon of a retractable engine or the consumption of turbines. Besides that, such a propulsion blower can work like the turbine also at higher speeds. The retractable engine has the fundamental disadvantage that the propeller efficiency decreases suddenly at some speed. There is only a narrow band of operational speed.

Up to now, the diameter of a radial blower by means of the so-called elbow diffusers is relatively big. The elbow diffuser changes the radial flow direction into the needed axial flow direction. This problem is solved by the invention of the more space-saving and more efficient “Schräglippenspirale”, the sloping lip spiral, DE-10-2007-055507, that was presented first at the 2007 Segelflugsymposium.

The objective since 2008 is an optimization of the present propulsion blower. This happens by enlarging the cross section and by using better blower wheels for high speeds. Such radial blower wheels are not on the market; they have to be manufactured by hand. However, a method was developed to produce glass fiber blower wheels with profiled blades.

The transition between propelled flight and free flight occurs through opening or fastenings of suction and propulsion opening flaps.

The “relatively” heavy engine, the yellow box in Fig. 2, is shown before the center of gravitiy, while the blowers are in the body tube behind the wing connections. The fuselage tube is an empty unused area which serves primarily as a bearer of the tail unit and for the guidance of the steering rods.

The Functional Model FM-10 with two beetle-blower wheels reached 2008 with a Göbler Hirth F33 engine producing 140N of thrust, sufficient for a sustainer unit.

A new blower construction will generate 300-500N thrust. With such a unit, the takeoff speed of a sailplane can be reached. The present rolling construction will be substituted with the fuselage of a Club Libelle H-205 that rolls on the wheels of a Remoqueur towing plane. These wheels became available after the plane crashed.

Figure 3 -Test-trolley 2008 in Günterrode airfield, rolling wheels for a Club-Libelle fuselage 2012 KW-45 in front of the Flugwissenschaftliche Fachgruppe Göttingen, FFG

New Developments in 2013

Molds for the construction of the blower, shown in Fig. 2, should be made or milled in the course of 2013. The further development of an achievable and easily produceable and efficient blower wheels will also be pursued.

1. The new blower installation should be tested in a fuselage – Club Libelle.

2. An F33 Göbler Hirth engine is available now.

3. I have also in mind to use 20 kW electric motor (e.g. Emrax) to handle problems with exhaust gas, heat flow, and vibrations.

If these preliminary works are successfully, the real aim of the work can be tackled, the construction of an airworthy functional model.

This work is being carried out within the facilities of the scientific flight professional group Goettingen, FFG, Flugwissenschaftliche Fachgruppe Göttingen. They are supported by many people from the DLR and from the community of soaring enthusiastics, and of course by the members of my gliding club, the FFG. At this point, I would like to thank all these people expressly.

Benefits and Possible Spinoffs

The development of this propulsion blower has led to many new results, including, among other things, a new spiral geometry and blower wheels. Narrow-building relatively unefficient blowers are used in many applications. Progress in the Jet-Glider project can be applied to technical developments in quite different areas, e.g., in the pneumatic conveyor technology or in the room air conditioning technology. However, a new blower is easier to insert in a vineyard syringe than in a sailplane.

A Jet Glider offers the big advantage of speed and the extended range. This makes a Jet Glider an aircraft suitable for touring flight or wave soaring—and a Jet Glider can be a self-launcher. How the security aspect and the cost aspect compare to today’s state of the art, only experience can reveal.

The Future of Soaring

In our changing world—at least already in Germany—we are currently seeing the extinction of the private airplane with fuel hungry engines, at least in the community of private pilots. We are also witnessing the extinction—at least also in Germany—of gliding associations and their specific structures hungry for the leisure time of their members. Nobody wants to spend a whole day for two ten minute winch launches for soaring training. These times are over.

The first sailplanes were unique pieces built by groups of enthusiastics. The self construction of sailplanes has became less important since the 1960s. New sailplanes are very expensive because of the development costs, the labour costs, and the small market. These extreme costs for extreme improved planes are raised, so I suppose, more and more by individuals and less and less by gliding clubs and other associations.

Such a social surrounding does not automatically support a new idea like the Jet-Glider, at least not as long as no functional model flies. So I think it is better to rely on the old traditions and to build the planes with which we want to start and fly again independently of manufacturers. If there is success they will follow.

And a high risk must be balanced by a even bigger benefit.

To the advantages of the uncritical transition between propelled flight and soaring flight, the high speed and the low energy consumption, the long range and the opportunity to motor home or to the possibility of self launch, still can be added another most important point of view.

The most important difference from other propulsion systems is that the Jet-Glider has a strong suction blower as a propulsion blower. This offers the strong possibility that the thoughts of Betz and Pfenninger concerning boundary layer control, “Grenzschichtabsaugung,” can became reality.

This is a very old dream which can come true if we work in this direction of development and neglect to follow the “scientifically approved, serious and secure” mainstream of developments.

For more information, visit www.strahlsegler.ploland.de .

Plotter/ Georg E. Koppenwallner plotter@ploland.de

Strahlsegler patents:

DE-000010300621B4 Strahlsegler, Jet-Glider – granted

DE-10-2007-055507- Schräglippenspirale, Steep lip spiral – applied

DE-10-2010 -023017-A1 i.a. Boundary-layer suction -applied

[1] Bundesanstalt für Flugunfall Untersuchung = Federal institution for flight accident investigation

2 comments for “A Jet-Glider (Strahlsegler)”