Author Dafydd Llewellyn—now retired—has been an unlimited Australian structures DER for 37 years, and was the designer of the L-13A1 Blanik modification, in 1978. For more about the Blanik Life Extension Program, based on Mr. Llewellyn’s modification, click here.

They CAN be made to fly again, but not by spraying them with “Crack Bane.” It’s time to leave denial and wishful thinking behind, and start to face facts:

There is nothing mysterious about the fatigue life of a metal aircraft structure; you can look it up in FAA Advisory Circular AC 23-13A. Every stress cycle takes a little bit out of the life of the structure. It does for glass, too, but not in quite the same way as for metal.

A stress cycle is defined by the mean stress, and the alternating stress. For each combination of mean and alternating stress, the structure will withstand a certain number of cycles before it fails. How many cycles it takes at each combination of mean and alternating stress, was the subject of intense study after WW2; 100 sets of surplus P-51 wings were tested to destruction in Australia, and this provided most of the data shown in Figure A2-1 in Appendix 2 of AC 23-13A (known as the “Heywood Joint” data). These data were also used by the Czech VZLU in their fatigue life calculations for the Blanik, in 1977. We are still using these data today.

The other factor is, of course, the usage to which the aircraft is subjected. The higher the stress, the shorter the life, so when estimating the fatigue life, it is critically important to estimate how many cycles of each “G” level the aircraft will, on average, suffer each flying hour. This is called the “Load Spectrum”. The Czech VZLU used a spectrum derived from experience in the Czech usage of the Blanik. (This was later compared with a measured spectrum for an Australian Blanik, and was found to be realistic, for normal soaring and training usage).

How can an aircraft designer set the intended service life? By choosing the stress level in the critical parts of the structure, at 1G. The 1G stress level for the L-13 is around 6000 psi. That was suitable for the original design requirement for the L-13, of 3000 hours safe life. The Czechs announced this in 1977; however in most parts of the World, people did not concern themselves about the fatigue lives of light aeroplanes, let alone Gliders. So in most parts of the world, including the U.S.A., nobody took any notice of this announcement. You were told, but you did not listen.

In Australia, because of the generally good flying weather, aircraft accumulate hours faster than in most of the rest of the World; and the summer turbulence is pretty strong. So there had been a number of fatigue failures of aircraft of various types (including a Vickers Viscount), and the Czech announcement did not pass unheeded. There were several specimens in Australia that were well past the 3000 hour figure, when that announcement was made. So the Czechs put a Blanik in their fatigue test rig and tested it until it failed, persisting until all the critical failure locations had been identified. As a result of these tests, the life was extended to 4000 hours (aerotow)/ 3750 hours (winch).

However, the only way to achieve a substantial increase in the life of an aircraft structure, is to reduce the 1-G stress. That means, add more metal – and replace as much of the original metal with new material as is practical. To take a Blanik that had flown 4000 hours, and give it a useful new lease of life, requires that the items that can be, are replaced; and the total amount of new material reduces the 1-G stress sufficiently to extend the life. In the critical zone at the wing root, that requires that the 1-G stress be less than half its original value. There are other high-stress spots further outboard, and elsewhere, that must also be suitably reinforced. In all, to extend the life to three times its original value, requires approximately 22 Lbs of additional material. Most of this goes inside the wing; but some must go outside.

Where does eddy-current testing of the fastener holes fit into this?

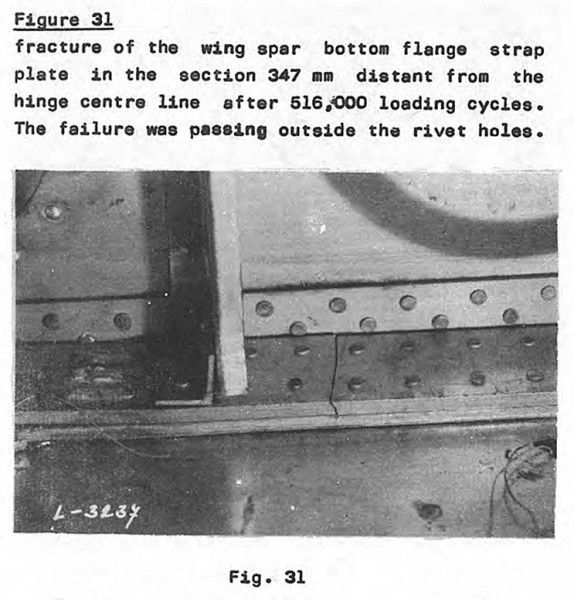

Nowhere; because in the original Czech tests, the initial failure occurred in the internal strap—and it DID NOT go through the holes:

Fig. 31 is an excerpt from the Czech Aeronautical Research & Test Institute (ZPRAVA VZLU) Report Z-31, 1977, titled Fatigue Life Analysis of the L-13 (Blanik) Glider, author Vaclav Kahanek. The report is in English.

This failure occurred at 516,000 loading cycles—and the main extruded angle failed after two more cycles, causing catastrophic wing failure.

So there is no “magic feather” that will allow Blaniks to fly again with a useful extended life; the wings have to be opened and reinforced, and other critical points in the structure must be likewise replaced or reinforced, and that it all there is to it.

Why would one go to this expense for a glider that had a market value of around $10K before the grounding? Well, before the grounding, that glider was nearing the end of its existing fatigue life, and was also about due for its 40-year inspection.

What is its value after it has gained another 8000 hours of life, and passed its 40-year inspection? Still $ 10K ? Hardly. Doing all this work costs around $40K—with a full refurbish, probably nearer to $50 K. Reckon you’d still buy it for $10K after that? Don’t be silly; the market value will increase, probably to around $60 K.

So, why would you spend this amount of money? Because the cost of hull amortization per flying hour is half that of any new 2-seat training glider.

Use some common sense, please. Yes, it’s a pain to have to do this now, when an extra 20 odd pounds of metal in the original aircraft would have avoided the problem – but how was LET to know what a success the Blanik was going to be, back then?

I’m hoping that this modification will shortly become available in the U.S.A., but that depends upon factors that are outside my control.

26 comments for “What’s the Answer to the Blanik Issue?”